|

| CF-3 Catches a Wire at Lakehurst |

The U.S. Navy’s carrier-based version of the Lockheed Martin F-35 Lightning II Joint Strike Fighter is nearing October sea trials after completing shore-based testing at Naval Air Engineering Station Lakehurst, New Jersey, to ensure compatibility with shipboard arresting gear.

“From 9 to 16 Jan, the F-35 team accomplished 36 successful roll-in arrestment tests at Lakehurst with the redesigned F-35C arresting hook system on CF-3,” wrote Joe DellaVedova, a spokesman for the F-35 Joint Program Office in a Tuesday email to USNI News. “All flight test objectives were met.”

|

| Tailhook too close to Landing Gear compared to other Carrier Aircraft |

The Aviationist » "F-35C unable to land aboard aircraft carriers" report says. U.S. Navy and Royal Navy have something to be worried about.

During specific tests conducted at NAWC-AD (Naval Air Warfare Center – Aircraft Division) Lakehurst, the F-35C failed to engage the MK-7 arresting gear with a disappointing score of 0 successes in 8 attempts. Considered that arrestment testing takes place on a normal airport, without the thrill of bad weather, pitching deck, nearby obstacles, low fuel, lack of alternate airfields and all those factors that make a trap on an aircraft carrier the scariest kind of flying.

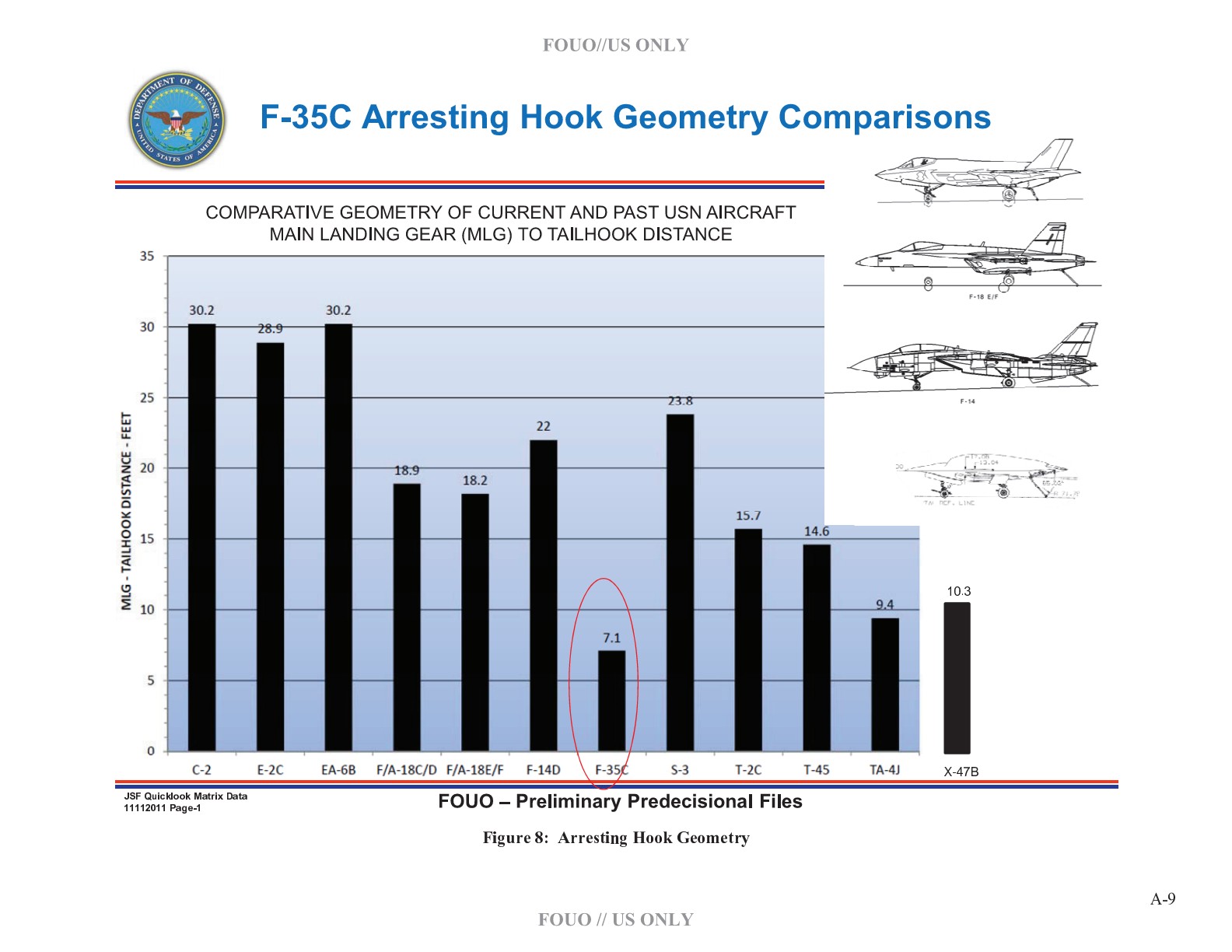

Root cause analysis points to some AHS (Arresting Hook System) design issues:

- aircraft geometry (short distance between the Main Landing Gear tires and the tailook point)

- tailkook point design, with scarce ability to scoop low positioned cables

- tailkook hold-down ineffective performance in damping bounces relative to the deck surface profiles.

|

| Redesigned hook |

Lockheed promises tailhook fix to Navy’s F-35C | DoD Buzz

One of the problems was the initial design of the tailhook, which was a challenge for Lockheed Martin in that it had to be concealed within the airplane to enhance its stealth capability.

In testing, the tailhooks were failing to catch the arresting wires that are stretched across a carrier’s flight deck to bring the aircraft to a halt.

“Our original design was not performing as expected,” said Lorraine Martin, Lockheed Martin’s executive vice president for the F35 Lightning II program. Martin said the “toe” of the tailhook, the part that grabs the wire, had been re-designed along with the “hold down damper” gear that forces the tailhook down on the deck.

No comments:

Post a Comment